Dynatek make ‘AMF CONTROLLER‘ is one of the most user friendly, Highly reliable & compact microcontroller based AMF Relay system. It is cost effective solution for AMF Controlling system. Most advanced technology is used to provide maximum features required for AMF Controlling system. It offers annunciation and controlling with Audio / Visual signal & potential free o/p contact. It works in Auto, Manual & Test mode. When AMF CONTROLLER is in Auto Mode, it continuously scans the mains supply. If Mains supply fails for specific period the controller starts cranking the DG set through start relay. Controller undertakes the set attempts.

In case if it fails to start the DG after the set attempt it annunciates accordingly and turns ON hooter for Audio signaling. If DG starts in any of the set attempt it allows DG to reach its operating speed to build up the required voltage and then it puts the load on DG by closing DG contactors automatically.

On the resumption of healthy mains with required level of mains voltage controller connects the load on mains after the set delay periods & DG set is returned to standby mode for further operation after the required ideal running ( Cool - Off Delay). In manual mode Controller does not react to Mains failure or Mains restoration. All the operations are to be done manually. Controller is suitable for both 12V & 24V since it has wide operating voltage range ( 7 VDC to 30 VDC).

The Controller is equipped with built - in circuit for sensing the battery Voltage. If the operating voltage goes below 8 V ( For 12V DC System) or 17 V ( For 24V DC System) , the controller indicates “LOW BATTERY” alarm.

Various Time Delays -

1) Start Delay : After the Mains fail, the controller will wait for specific time to ensure the continuous failure of Mains before going for DG start - Up cycle.

2) Mains Return Delay : The controller will wait for specific time before putting the load from DG to Mains after the resumption of healthy Mains.

3) DG Warm-up Delay : The system to allow DG to run idle for specific time before putting the load on DG.

4) DG Cooling Time : The system to allow the DG to run idle for specific time before cut - off fuel supply to DG.

5) Crank On Time : The System allow the cranking for specific Seted time.

6) Crank Off Time : Silent timing bet’n two cranks.

| Fault Input Points | - | 10 Nos. |

|---|---|---|

| Power Consumption | - | 9 Watt |

| Weight - | - | 300 gms. |

| Window indication | - | Bright Red LED Display |

| Fault Inputs | - | Potential free contact : “NO” or “NC” |

| Flashing rate | - | For first fault 300 flashes / Min. & Subsequent fault 60 flashes / Min. |

| Hooter Relay contact Rating | - | 250mA / 230VAC, 1A / 24 VDC It is advisable to connect additional relay for heavy load |

| Relay Contact rating for “START”, “STOP or Fuel” Solenoid | - | 3A / 230 VAC, 5A / 24VDC It is advisable to cascade relay for heavy load. |

| Relay Contact rating for “Mains and D.G. Contactor”. | - | 3A / 230 VAC, 5A / 24VDC It is advisable to cascade relay for heavy load. |

| Additional open collector o/p for each channel for mimic or remote display | - | 100 mA Sinking mode |

| Operating Supply | - | 24 / 12 VDC |

| Mechanical Details | - | |

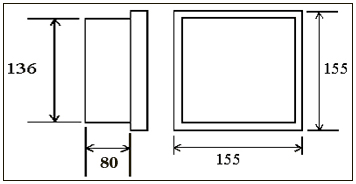

| Bezel Size Cut out Size | - | 155 X 155 mm 138 X 138 mm  |

| • | Based on latest “Micro-controller” technology. |

| • | Sleek, Compact design for reliable and accurate operation. |

| • | Series of super bright LED's instead of twin filament lamps for ultimate life at very less power consumption. |

| • | Fault input contacts NO/NC site selectable by means of DIP switches. |

| • | Opto-isolated all fault inputs, immune to noise disturbances. |

| • | Provision for external audible (Bell or Hooter) thro' potential free relay output contact. |

| • | Built-in feather touch push buttons for Test, Accept and Reset, Auo / Manual, Start, Stop functions. |

| • | Various Settings Provided by Dip Switches : No. of Crank Attempt, Crank On Time, Crank - off Time. |

| • | Relay o/p for 1) Start Solenoid 2) Stop solenoid |

| • | Two part connector ensures easy replacement and service at site. |

| • | Suitable to all Diesel Engine ( Start Solenoid or fuel Solenoid) |

| • | Auto and Manual Mode. |